The features of Magnetic Couplings The features of Magnetic Couplings

|

|

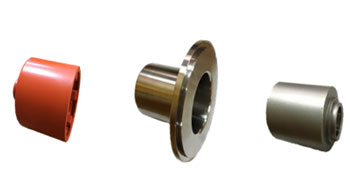

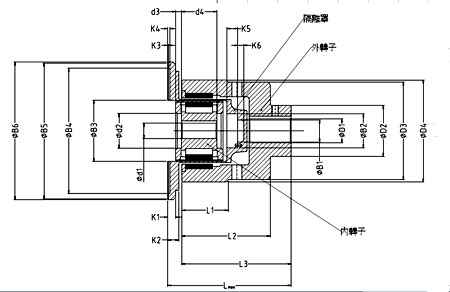

»Magnet coupling designed to transmit torque using the magnetic field that is established between the inner and outer rotor without mechanical contact between shafts. The magnetic couplings create neither slippage nor induction current during rotation. The magnets are installed alternating between poles in a side by side and opposing position. The inner and outer magnetic rotors are locked together by magnetic forces and work as a synchronous coupling. The use of magnetic couplings is recommended in applications where it is necessary to hermetically separate two zones in order to prevent fluid or gas leakage from one area to another. The classic example is fluid transfer pump applications. In these applications the fluid must not come into contact with the external environment. These magnetic couplings also prevent transmission of vibration and axial and radial loads through the drive shaft. |

1.Zero pump maintenance - |

| |

»They work free of wear. Vibrations are not transmitted to the pump. There is no more the requirement to periodically check/change the sealing. The maintenance cost drops down drastically. |

2.No leakage - |

| |

»The isolation cover is mounted on the pump end and the ability to hermetically separate two areas to prevent fluid or gas from leaking to another area to avoid serious leaks. |

3.Component protection - |

| |

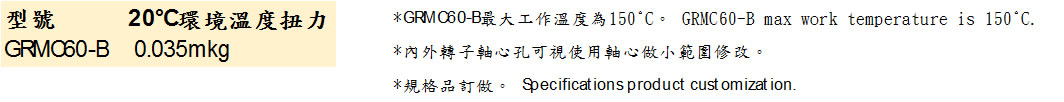

»If the pump requires a torque (power) bigger than the maximum allowed, the magnets will decouple, they will not recouple unless the pump is stopped. |

4. Application |

| |

»Medicine

Chemical industry

Oil and gas industry

Refining technology

Pharmaceutical industry

Food industry

Centrifugal pumps

Gear pumps

Screw pumps

Especially for flammable, explosive, volatile, toxic, conveying high temperature, strong acids and alkalis, organic solvent and precious liquid. |

![]()